Rotary Screw Compressors also use two inter-twined helical shaped screws, often known as rotors, to compress the air. These rotors are precision machined to particularly restricted tolerances, whereby the vanes over the rotors are Virtually touching, and commonly only a few thousandths of an inch apart.

Find out more Company in the USA Check out our wide array of assistance solutions, starting from assistance plans and components ideas to piping and installation, program style and design, and air audits and air analysis.

Customer support With service centers nationwide and our 24-hour emergency areas assure, Kaeser prospects can rely upon the top after-profits assistance from the sector.

CNC machining facilities, laser and plasma cutters, as well as paint/coating spray functions are all examples of purposes Which may be a lot more effective with rotary screw compressors. Listed here is a straightforward infographic evaluating vital elements you should look at when determining concerning a piston or screw compressor. For a more in depth evaluation, down load our free white paper.

Anxiety within the cylinder body of the pressure vessel. Tension in a thin-walled pressure vessel in The form of a cylinder is

Find out more Beer, Beer, and even more Beer! From compressors to nitrogen generators to blowers, We have got The perfect suite of products that assist your brewery brew the perfect pint at the lowest expense of ownership.

At a set position wherever the top edge of the flute and the sting in the discharge port co-inside, compression ceases and also the air is discharged in to the shipping and delivery line, until eventually the flute quantity has actually been lessened to zero.

Freezing: Surplus moisture can freeze in cold climate triggering a buildup on top of things strains, leading to defective working.

Find out more Beer, Beer, and More Beer! From compressors to nitrogen turbines to blowers, we've got The perfect suite of products that enable your brewery brew an ideal pint at the lowest price of possession.

Learn More Company while in the USA Take a look at our wide array of service possibilities, ranging from assistance ideas and components designs to piping and installation, procedure layout, and air audits and air analysis.

The material absorbs the ultrasonic audio waves and turns them into an electrical signal via a transducer. If there transpire to become any flaws current, the mirrored waves might be disturbed.

Electrical power successful Sigma Profile airend creates extra air with considerably less horsepower Heavy-obligation 3-cylinder diesel engine fulfills Tier four Ultimate EPA emissions standards Sigma Handle Good electronic controller in the eye-amount, rear side instrument panel with protecting metallic include Further-large 21 gallon fuel tank for approximately eight continuous hrs of Procedure High capability chilly get started battery ensures reputable operation Anti-frost valve maintains ideal functioning temperature and prevents Software freeze up

Backward extrusion: A system by which the material is compelled to flow back alongside the mandrel concerning the mandrel and die.

Simplicity of fabrication and routine maintenance – Metal sheets need to be machinable and weldable to type the pressure vessels’ geometry. It will likely be easier to set up the here vessel’s internals by doing this.

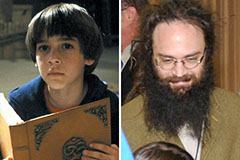

Barret Oliver Then & Now!

Barret Oliver Then & Now! Burke Ramsey Then & Now!

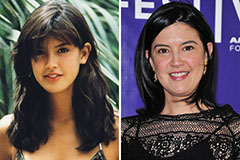

Burke Ramsey Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Shannon Elizabeth Then & Now!

Shannon Elizabeth Then & Now! Ricky Schroder Then & Now!

Ricky Schroder Then & Now!